The problem

In the real world, the customer always wants fast and certain delivery times. The salesperson is often forced to confirm the delivery date, without actually knowing what it takes to respect them. This happens because the salesperson is lacking the tools to allow him to evaluate the impact that those requests have on the company’s activities.

Basically, it is as if he had to catalog the content of a very large dark room, while using only a match. He would always see only a small portion of the room and, once arrived at the end, he should remember everything that he has previously seen.

The consequenes of this situation can be often disastrous:

WITHIN THE COMPANY

- Continous emergencies in the factory to meet delivery times.

- Difficulty in the planning of re-orders with consequent increase in purchase costs.

- Lost of cash if deliveries do not happen.

OUTSIDE THE COMPANY

- Unsatisfied customers who order less or go to competitors.

- Damages to the brand credibility that can be worsened due to the word of mouth.

REQUESTS

The customer asks us several requests:

- I need it immediately, do you have it in the warehouse?

- I need it in a week. Is it possible?

- When can you deliver it to me?

VARIABLES

The variables to take in consideration are a lot and often in conflict with one another:

- Do I have availability in my warehouse?

- Do I have availability in a secondary warehouse?

- Did I use the availability to satisfy other customers’ orders?

- To which customer do I have to give priority?

- Do I have productions in progress that may serve the request?

- Can I buy it from third parties?

CONSTRAINTS

But also constraints:

- This customer is important and I cannot let him down.

- I already exposed myself promising delivery dates that must not be changed.

- That production has already been promised to another customer.

- Goods are coming but they have already been reserved for another order.

CHANGES

Moreover, decisions must be taken in an ever-changing situation:

- New orders arrive.

- Existing orders are modified and can be partially or completely cancelled.

- Warehouse availability continously changes depending on the incoming (from production and purchase) and outcoming (from shippings) materials.

Do you have similar problems?

See Stockforce Plan with your own eyes.

One of our experts will guide you through the choice, understand your peculiarities and clear your doubts.

The solution

To guarantee this result, the planner elaborates the immediate and future needs and availability in real time while managing all the variables involved by proposing reasonable and feasible delivery dates.

It will ensure that the promised dates won’t be neglected, reserving the availability for the confirmed orders and elaborating those that are not.

Manually or automatically confirmed dates create the company delivery plan that allows all departments (commercial, production, sales, delivery) to move together for a shared goal: give solidity and certainty to the deal done with the customer.

MOX.PLAN goes further allowing the delivery plan to increase the warehouse work generating missions that can be fulfilled in a traditional way or through PDAs. If using these last ones, it allows you to check the delivery status in real time.

This guarantees the possibility of verifying if what has been planned can be actually carried out by the warehoue department or if promt countermeasures must be taken.

Ready to start?

See Stockforce Plan with your own eyes.

One of our experts will guide you through the choice, understand your peculiarities and clear your doubts.

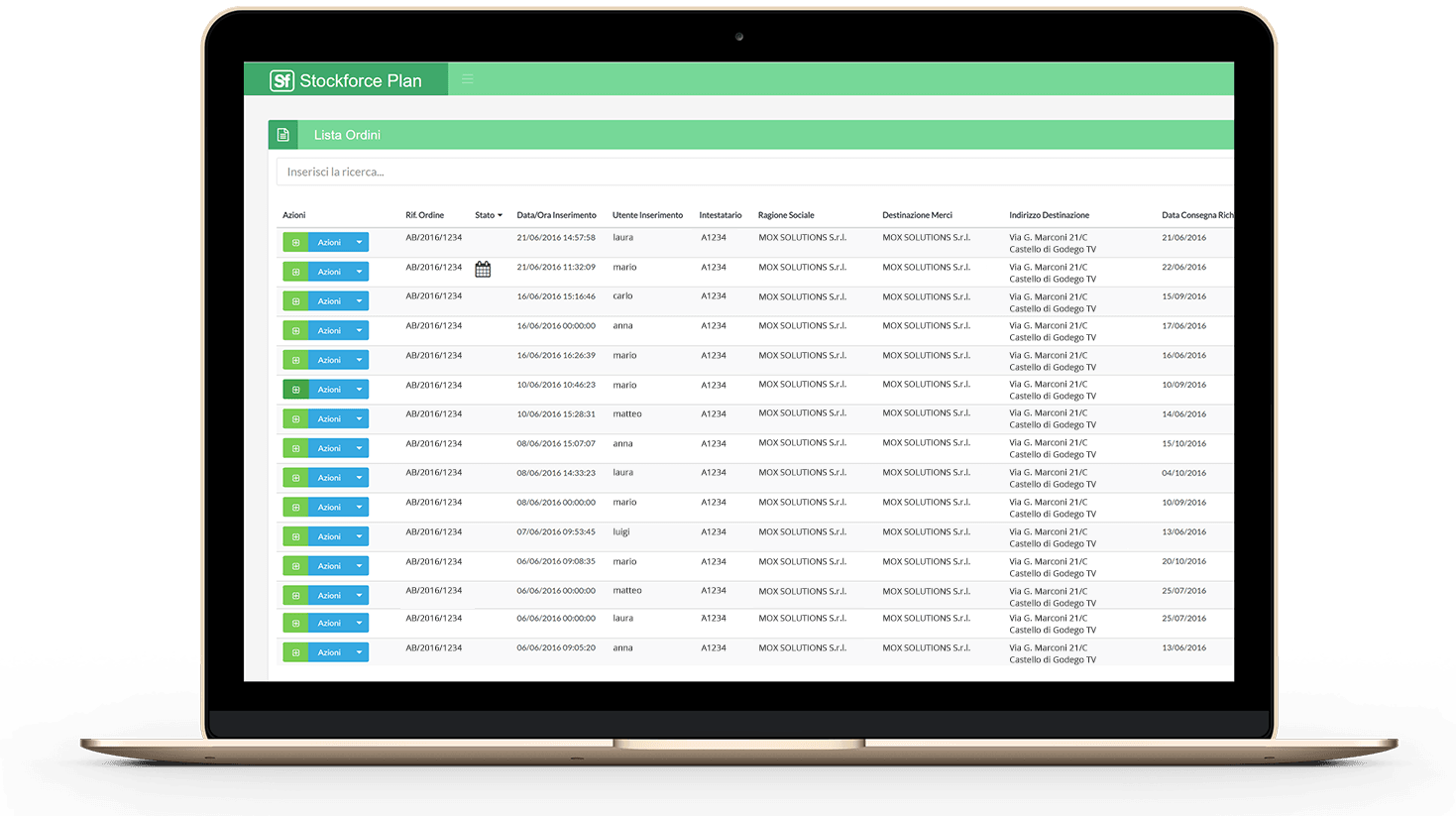

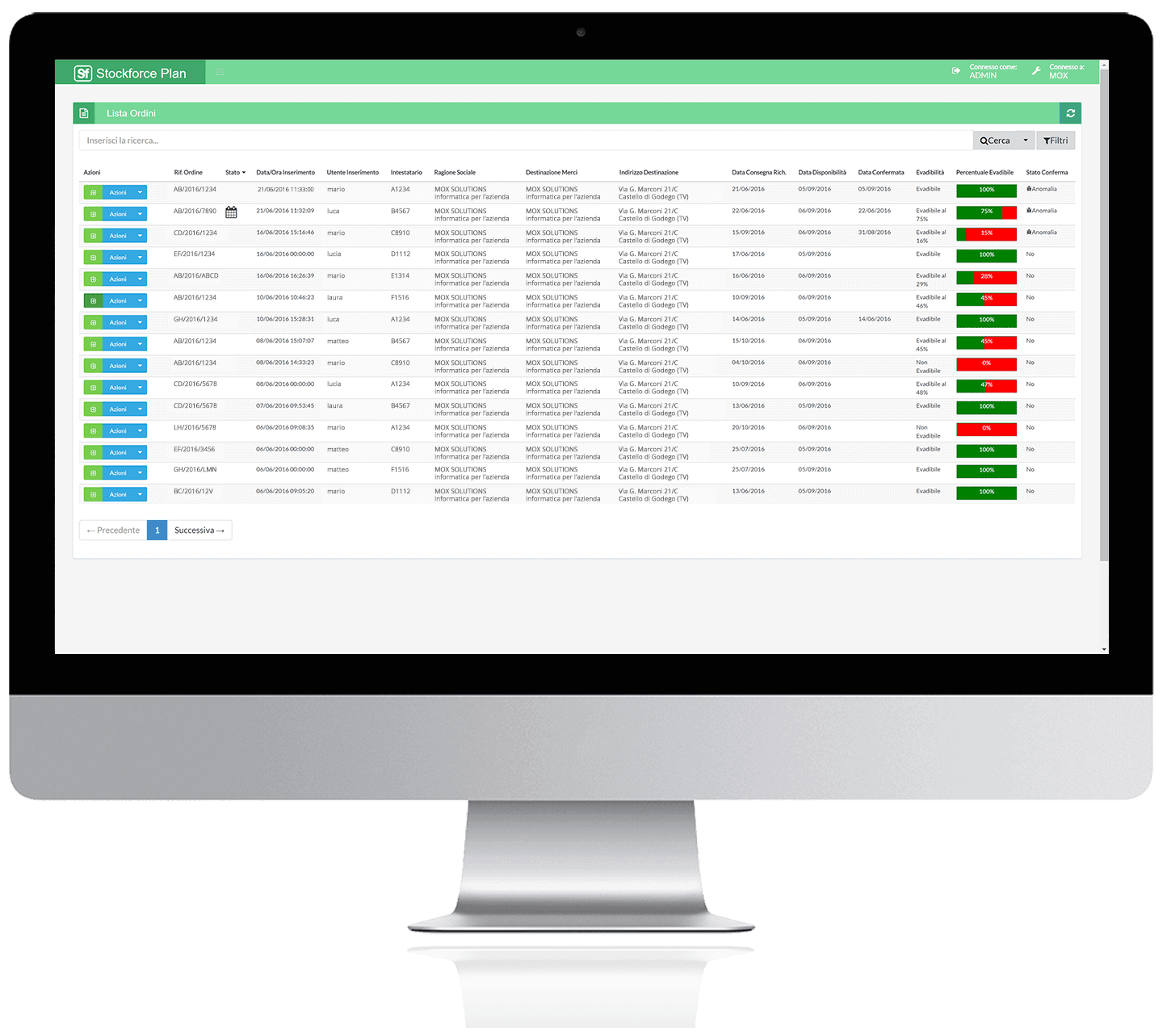

Orders planning

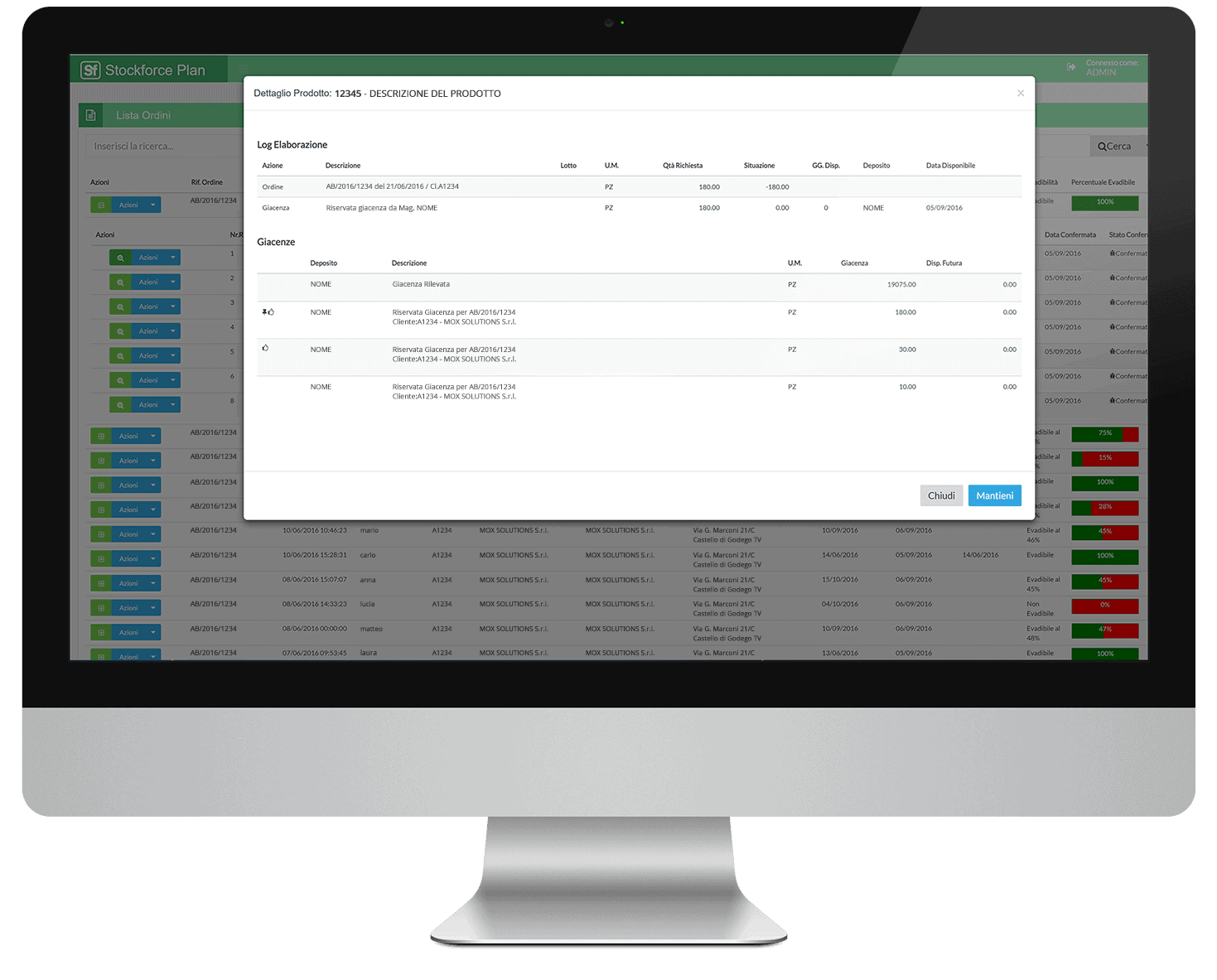

Plan processes the orders portfolio in real time and puts it in relation with current and future availability proposing a delivery plan that takes in consideration all the entered parameters (make or buy, transfer and preparation times, production lead time, …).

Deliveries planned in this way are displayed on a console that immediately highlights the fulfillment and potential critical issues both by order and by single line.

Dynamic reservation of availability

Availability is calculated and dynamically reserved based on:

- Stock immediately available on the main warehouse.

- Stock immediately available through transfers from secondary warehouses.

- Future availabilities coming from supplier/production orders.

In case of unavailability, plan elaborates the possible delivery date thanks to:

- Production request (Make)

- Purchase request (Buy)

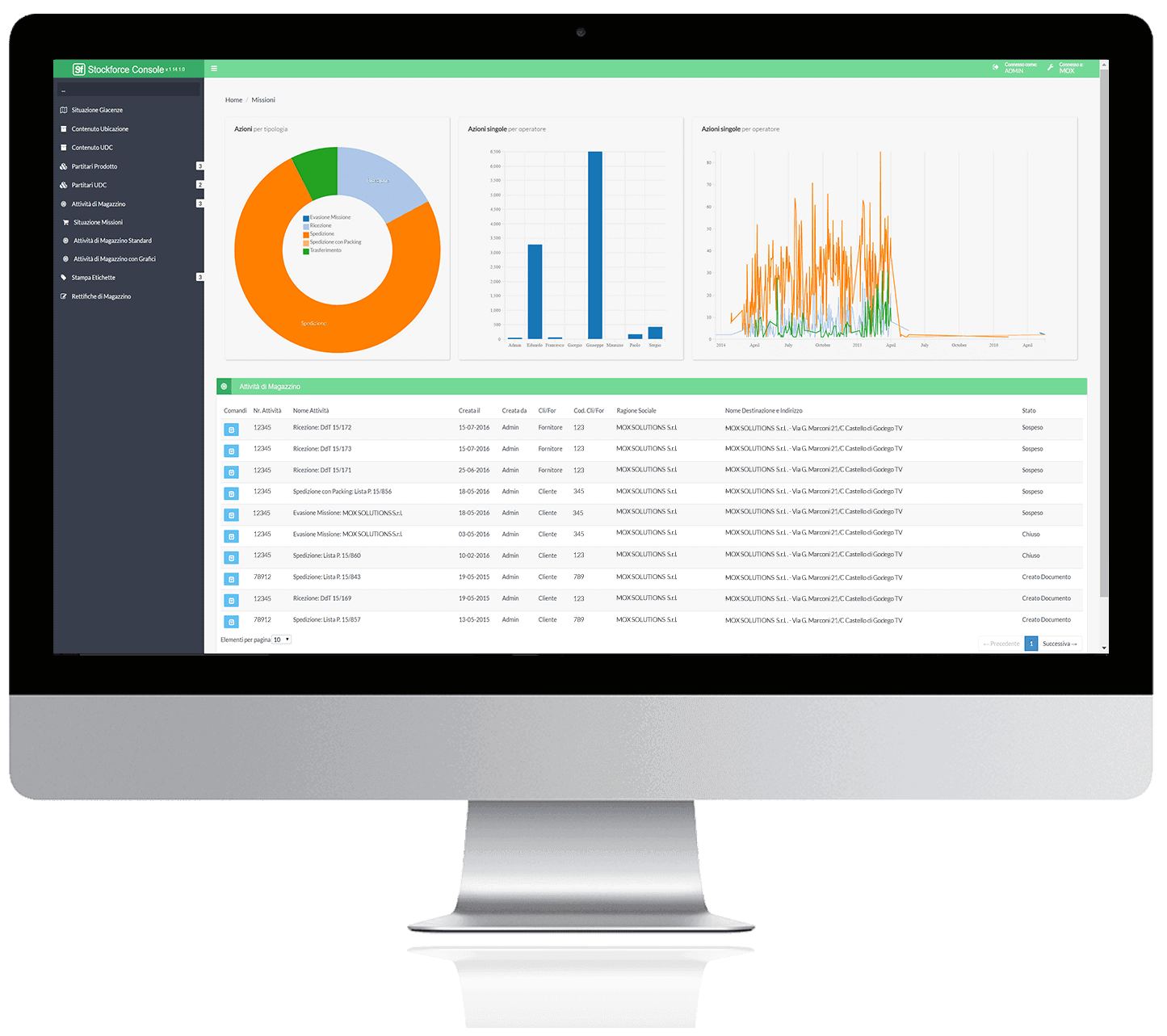

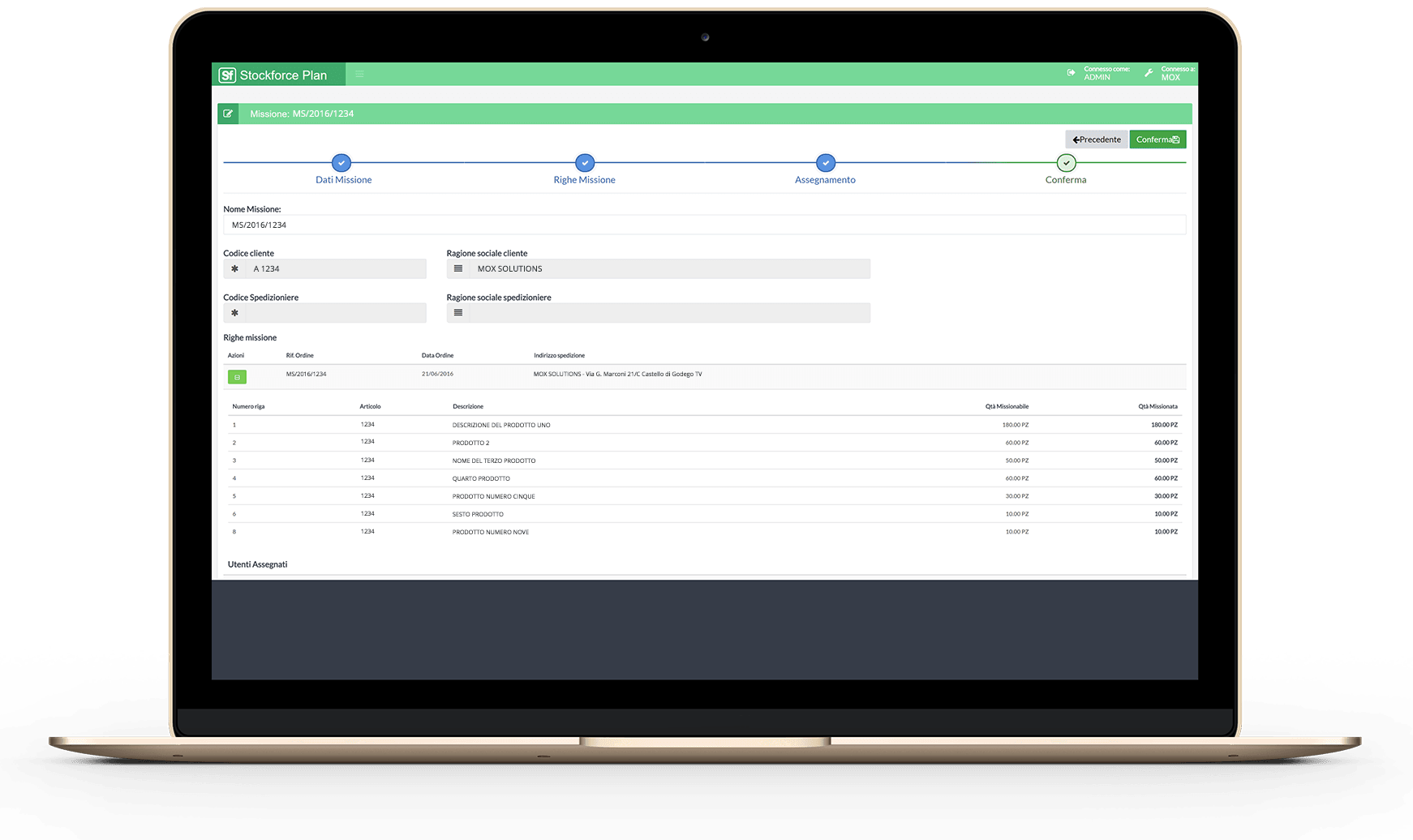

Mission release

Confirmed orders are released to the warehouse under the form of Missions.

Based on work necessities, the warehouse manager will be able to group multiple orders in one mission, as well as split a single order in multiple missions.

At any time, he will be able to see the warehouse workload thanks to graphs that will allow him to establish possible saturation of the area and take the necessary countermeasures (change of dates or overtime).

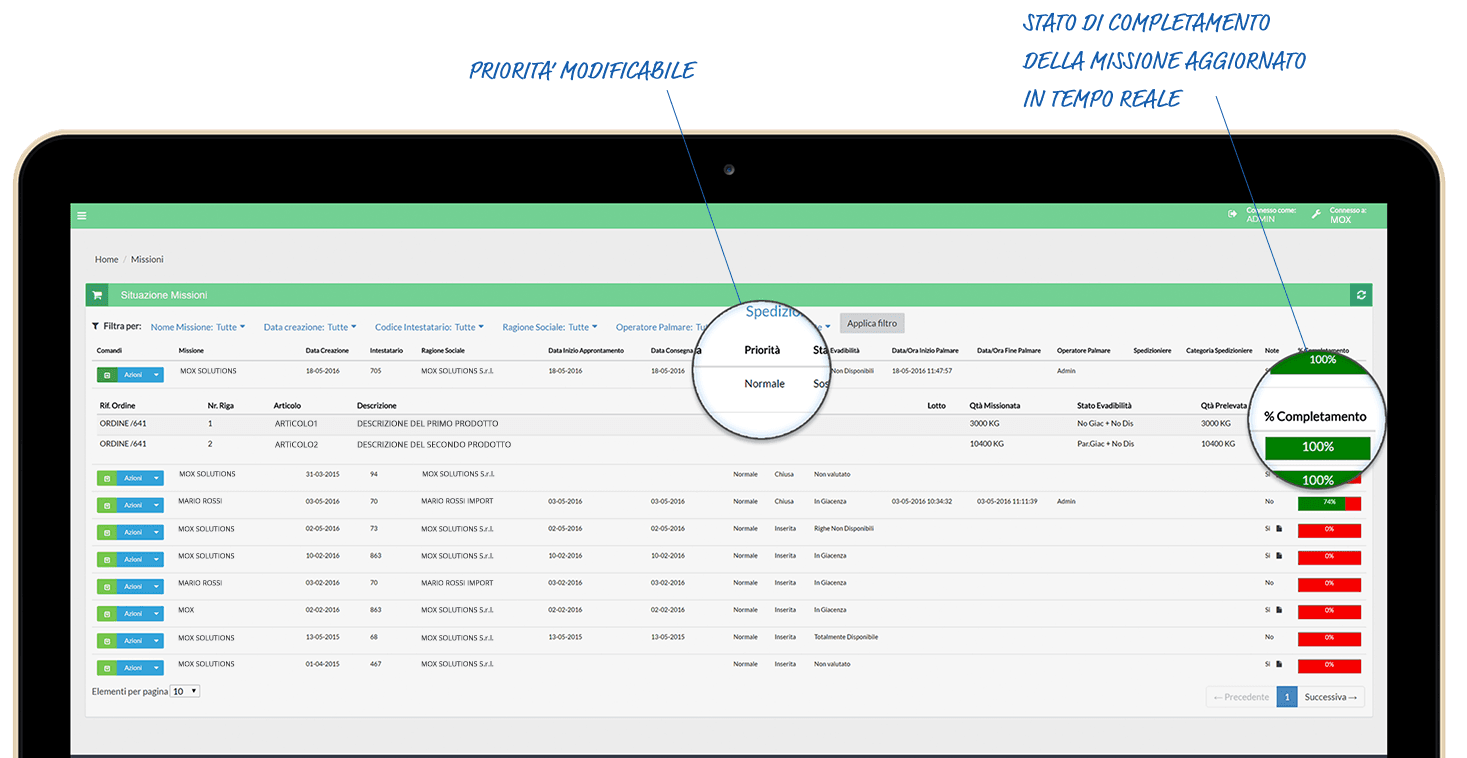

Control of warehouse activities

Checking the activities in progress in the warehouse is essential to understand if what has been forecasted can be followed. Otherwise, countermeasures must be taken.

Through the use of PDAs and the Stock app, the mission status is updated in real time, allowing a real comprehension of the warehouse dynamics.

Book a demo!

Book a free demo with one of our experts to discuss your needs and see how the platform can support you and your team’s work!

By clicking on “Send” you agree to the Terms and Conditions described in the privacy policy.

Technology

Plan is developed with web technology that allows it to be used on any device with a browser.

Installation

Installation is centralized on a server, making updates simple.

Integration

Plan is perfectly integrated into SellMore, ShowK and Stockforce WMS, allowing you to manage all the company’s processes with just one package.

Real Time

Plan intercepts all the management events in real time and it reschedules the situation.